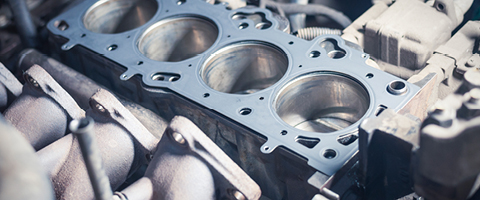

What is a cylinder head gasket?

The head gasket is one of the most important gaskets in the engine. It seals the passages between the engine block and the cylinder head, enabling oil and coolant to circulate in the engine without leaking into the cylinders or outside the engine. The head gasket also acts as a force transmission element, influencing the distribution of the force being generated by the cylinders.

The high combustion power of modern engines means the head gasket must be strong enough to withstand very high temperatures and pressures. In the past, head gaskets were often made of copper or composite materials that typically contained graphite. Today, most head gaskets are made of multi-layer steel (MLS), which consists of two to five layers of thin steel coated in rubber.

Even though head gaskets are pretty tough these days, they are still subject to wear and tear. If something goes wrong with your head gasket, oil and coolant can leak into parts of the engine where they don’t belong, compromising safety and causing costly damage. That’s why a leaking head gasket needs to be replaced as soon as possible.